What size are sectional garage doors?

Sectional garage doors vary in size, typically ranging from 8 to 24 feet in width.

Standard Sizes for Residential Sectional Garage Doors

Single Car Garage Door Dimensions

Single car garage doors are typically designed to fit one vehicle, either a car or a small truck. The standard dimensions for a single car garage door are:

- Width: Between 8 to 10 feet

- Height: Between 7 to 8 feet

However, these dimensions can vary depending on the specific vehicle or if there are additional storage or workspace needs within the garage.

For those interested in further specifications, Wikipedia has an in-depth article on residential garages and their variations.

Double Car Garage Door Dimensions

Double car garage doors, as the name suggests, are meant to accommodate two vehicles side by side. Here are the typical measurements:

- Width: Between 16 to 18 feet

- Height: 7 to 8 feet

These dimensions ensure that larger vehicles such as SUVs or vans can comfortably fit side by side. However, those with larger trucks or vehicles may need to ensure that the width and height are sufficient to prevent any scratches or damages when parking.

For detailed information about different car sizes and types, you can refer to this Wikipedia link.

Custom Sizes

For homeowners with unique requirements or architectural constraints, custom-sized garage doors are available. These can vary widely in both width and height, depending on the specific need. For example:

- For taller vehicles: Some might need a height of up to 10 feet.

- For wider garages: Widths can extend beyond 20 feet, especially if they’re designed to house multiple vehicles or serve other functions, like housing a boat.

The cost for custom-sized doors will significantly increase, often by 20% to 50% compared to standard sizes. The material quality, additional features, and the complexity of the design also play a role in determining the final price. Therefore, it’s crucial to budget appropriately and ensure that the custom size is genuinely necessary for your needs.

When considering custom sizes, it’s also essential to take into account the lifespan of the door. High-quality doors can last upwards of 20 years with proper maintenance, offering excellent value for the investment.

Commercial Sectional Garage Door Sizes

Small Commercial Garage Doors

Small commercial garage doors are suitable for businesses with limited space or for those that only require entry for smaller vehicles, such as delivery vans or compact trucks. Common dimensions include:

- Width: 10 to 12 feet

- Height: 8 to 10 feet

These sizes are ideal for establishments with limited parking or storage spaces. For a deep dive into the different types of commercial vehicles, check out this Wikipedia article on commercial vehicles.

Advantages of small commercial doors:

- Cost-Effective: These tend to be more affordable than their larger counterparts, with prices ranging from $1,000 to $2,500 depending on material and features.

- Efficient Space Usage: They fit well in tight urban areas or buildings with limited space.

However, their limited size may not be suitable for businesses that expect larger deliveries or have bigger service vehicles.

Medium Commercial Garage Doors

Designed for mid-sized commercial operations, these doors can accommodate larger delivery vehicles and service trucks. Their standard dimensions are:

- Width: 14 to 16 feet

- Height: 12 to 14 feet

Such doors are commonly found in facilities like larger workshops, small-scale warehouses, and some manufacturing units. For those curious about different warehouse types and sizes, this Wikipedia link on warehouses provides valuable insights.

Pros of medium-sized commercial doors:

- Versatility: Suitable for a broader range of vehicles.

- Durability: Often constructed with heavy-duty materials, ensuring longevity.

The cost for medium-sized commercial garage doors typically ranges between $2,500 and $5,000, depending on material quality, design, and additional features.

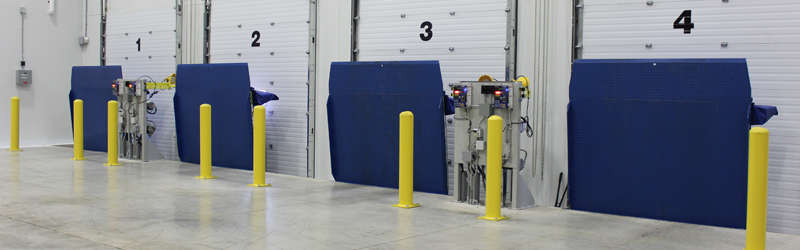

Large Commercial Garage Doors

Large commercial garage doors are tailored for expansive operations, accommodating large trucks, machinery, or multiple vehicles simultaneously. Typical measurements are:

- Width: 20 to 24 feet

- Height: 14 to 18 feet

You’ll find these doors in places like logistics hubs, large manufacturing plants, and big warehouses. For an in-depth understanding of logistics operations and large vehicles, here’s a Wikipedia page dedicated to logistics.

Benefits of large commercial doors:

- Space Maximization: Allows movement of massive machinery or multiple vehicles.

- Robust Construction: Built to withstand heavy usage and external elements, often made of top-grade materials ensuring longevity beyond 20 years with proper maintenance.

However, these come with a substantial price tag. Depending on specific requirements, material, and features, these doors can cost anywhere from $5,000 to over $10,000.

Factors Influencing the Size of Sectional Garage Doors

Garage Dimensions and Layout

The physical size and layout of your garage are primary determinants for the size of the sectional garage door you can install.

- Depth of the Garage: A deeper garage might accommodate larger or multiple vehicles, necessitating a wider or even a double garage door.

- Ceiling Height: Higher ceilings might allow for taller garage doors, which can be essential for high-roofed vehicles or if using overhead storage solutions.

- Side Clearance: The space on either side of the garage opening can dictate the width of the door, especially if there are structural columns or walls in close proximity.

Before settling on a door, it’s essential to measure the garage’s dimensions accurately. For more on how architecture can impact such decisions, check out this Wikipedia article on architectural design.

Vehicle Sizes and Types

The vehicles you intend to park in the garage play a significant role in the door’s size.

- Compact Cars: A garage meant for smaller vehicles like sedans or hatchbacks might not require an exceptionally wide or tall door.

- SUVs and Trucks: These typically require taller and wider garage doors to accommodate their larger dimensions.

- Specialized Vehicles: Vans with roof racks, trailers, or even some recreational vehicles might necessitate custom-sized garage doors to fit comfortably.

Understanding the variety of vehicles and their sizes can be better grasped by reading this Wikipedia page about car classifications.

Storage Needs and Usage

How you intend to use the garage beyond parking can influence the size and type of garage door you need.

- Workshop or Workspace: If half the garage is a workspace or workshop, you might not need a double door, even if the garage’s width might allow for it.

- Overhead Storage: Using overhead racks or lofts for storage might demand taller garage doors to allow for the vertical space used by stored items when lifting or moving them.

- Side Storage: If you have cabinets, shelves, or storage units lining the sides of your garage, it might limit the width of the vehicle space, affecting the door size required.

Cost is an ever-present factor when considering storage solutions and the resulting necessary garage door size. Additional storage or specialized doors might increase the budget, with specialized doors potentially costing 20-50% more than standard ones. The longevity of such an investment is crucial; with proper care, a high-quality door can last upwards of two decades.

Benefits of Correctly Sized Sectional Garage Doors

Enhanced Curb Appeal

A well-fitted garage door can drastically improve the overall appearance of a property.

- Symmetry and Proportion: A garage door that matches the size and layout of the house offers a harmonious and balanced appearance, adding to the property’s visual appeal.

- Material and Design: With the right size, homeowners have the flexibility to choose a design and material that complements the home’s architecture and style. For instance, wooden doors can add a touch of luxury to traditional homes, while metallic finishes might suit more modern designs.

- Increased Property Value: Homes with aesthetically pleasing exteriors, including well-sized garage doors, can command higher market prices. According to some real estate studies, homes with high curb appeal can see a price increase of up to 7%.

For a deep dive into how architecture and design influence property value, this Wikipedia article on real estate valuation offers valuable insights.

Efficient Space Utilization

Having a garage door that’s appropriately sized for the garage’s dimensions and intended use ensures optimal use of available space.

- Vehicle Movement: The right-sized door ensures easy maneuverability for vehicles, preventing potential damages during entry or exit.

- Storage Solutions: A garage door tailored to the garage’s dimensions allows homeowners to maximize storage solutions, be it overhead racks or side cabinets, without compromising on vehicle space.

- Workspace Comfort: If the garage doubles as a workshop, the right door size ensures efficient space utilization, giving ample room for tools, workbenches, and movement.

Efficient space utilization can also lead to cost savings in the long run. By maximizing available space, homeowners might avoid potential expenses related to external storage solutions or damages from cramped spaces.

Improved Security

A correctly sized garage door doesn’t just fit right; it also functions right.

- Snug Fit: Properly sized doors leave minimal gaps, reducing potential entry points for intruders or pests.

- Enhanced Durability: Doors that fit well and are made for the space they occupy tend to experience less wear and tear, ensuring they remain robust and secure for longer.

- Advanced Features: With a door that’s sized correctly, homeowners can also invest in additional security features, such as advanced locking systems or integrated alarms, further enhancing the property’s safety.

Security is paramount, and the right garage door plays a pivotal role in that. To understand more about home security and its importance, this Wikipedia article on physical security sheds light on the topic.

Potential Issues with Incorrectly Sized Garage Doors

Difficulty in Operation

An improperly sized garage door can lead to multiple operational challenges:

- Jamming: Doors that are too large for the frame can get jammed easily, making them hard to open or close.

- Gaps: Doors that are too small might not close securely, leaving noticeable gaps which can allow external elements like rain, snow, or pests inside.

- Mechanical Strain: Incorrect sizing can strain the mechanical components, like the springs and motors, especially if the door is automated. This can reduce the lifespan of the garage door opener, which typically lasts about 10-15 years with proper care.

For a deeper understanding of garage door mechanics and the importance of sizing, this Wikipedia page on garage doors is insightful.

Increased Wear and Tear

Improper sizing can escalate the wear and tear of the door and its components:

- Frequent Repairs: The stress on the door’s components can lead to frequent malfunctions, resulting in regular repair needs.

- Shortened Lifespan: A garage door that doesn’t fit right can wear out faster. While a correctly installed and maintained door can last two decades or more, an ill-fitting one might need replacement in just a few years.

- Additional Costs: More frequent repairs and replacements mean more expenses. An ill-fitted garage door can result in costs that are 30-50% higher over its lifetime compared to a well-fitted one.

Safety Concerns

A garage door that doesn’t fit correctly can pose significant safety risks:

- Falling Risks: An unstable door could fall, potentially injuring someone or damaging property.

- Security Breaches: Gaps or malfunctions can be an invitation to burglars or unwanted pests. Properly secured homes, including a well-fitted garage door, are crucial for safety.

- Fire Hazards: In cases where the door’s electrical system is strained due to improper sizing, there’s a risk of electrical fires.

For more insights into home safety risks and prevention, this Wikipedia article on safety offers valuable information.

Customizing Your Sectional Garage Door Size

Working with Manufacturers

When customizing your garage door size, partnering with a reputable manufacturer is paramount:

- Personalized Consultation: Many manufacturers offer personalized consultations to assess your specific needs, ensuring you get the right fit.

- Tailored Design: They can provide design mockups or CAD drawings, allowing you to visualize the end result before production begins.

- Material Choices: Depending on your aesthetic preferences and functional requirements, manufacturers can offer a variety of materials ranging from wood to steel, fiberglass, and even customized finishes.

To better understand the manufacturing process and the intricacies involved, you might want to explore this Wikipedia article on manufacturing.

Adjustments and Modifications

Customizing a garage door might involve several adjustments:

- Altering Dimensions: Based on your garage’s layout and usage, the door’s height, width, or both might need adjustments.

- Adding Features: You might want to incorporate windows, insulation, or specific panel designs to match your home’s aesthetic.

- Safety and Security: Modifications can include advanced locking mechanisms or integrated alarm systems, ensuring the door is not just custom in size but also in functionality.

For those interested in understanding the diverse range of modifications possible, this Wikipedia page on customization provides a broader perspective.

Cost Implications

Customizing a garage door does come with its financial considerations:

- Premium Pricing: Custom-sized doors often cost 20-50% more than standard-sized ones. The exact price varies based on the material, design, and additional features you choose.

- Installation Costs: Custom doors might require specialized installation, leading to increased labor costs. Typically, installing a custom garage door might be 10-30% more expensive than a standard one.

- Maintenance: Unique sizes or designs might demand specialized parts for repairs or replacements in the future, potentially increasing maintenance costs.

While custom doors come at a premium, they can offer unmatched aesthetics, functionality, and fit. However, it’s essential to budget appropriately, considering not just the initial expense but also potential long-term costs.