Infrared, ultrasonic, microwave, and laser sensors work alongside electric motors, hydraulic, and pneumatic systems to operate automatic doors efficiently.

Types of Automatic Doors

Sliding Doors

Sliding doors are perhaps the most commonly encountered type of automatic door. They usually consist of two door panels—one fixed and one mobile—that slide horizontally.

Components

Sensors: Often use infrared sensors or microwave sensors to detect motion or presence.

Actuators: Typically employ electric motors to slide the door horizontally.

Advantages

Efficient use of space

Quick and easy to use

Suitable for high-traffic areas like airports and malls

Swing Doors

Swing doors are similar to standard hinged doors, but they open and close automatically. These doors are prevalent in residential buildings and small commercial settings.

Components

Sensors: Commonly use ultrasonic or infrared sensors for motion detection.

Actuators: Hydraulic systems or electric motors are typically used.

Advantages

More conventional appearance

Ideal for places with less foot traffic

Can easily be manually operated if needed

Revolving Doors

Revolving doors consist of several leaves that rotate around a central axis. These doors are particularly useful in maintaining indoor climates and are frequently seen in large corporate buildings or hotels.

Components

Sensors: Often equipped with laser sensors for precise operation.

Actuators: Electric motors usually facilitate the revolving action.

Advantages

Energy-efficient as they prevent drafts

Can handle multiple people at once

Adds aesthetic value to the building

Telescopic Doors

Telescopic doors have multiple sliding panels that neatly tuck into each other when the door opens, providing a wider opening in a more limited space.

Components

Sensors: May use a combination of infrared and ultrasonic sensors for enhanced sensitivity.

Actuators: Electric motors are almost exclusively used for telescopic doors.

Advantages

Provide a wider opening without requiring more space

Modern and high-tech appearance

Suited for both commercial and residential use where space is limited

Overview of Sensors in Automatic Doors

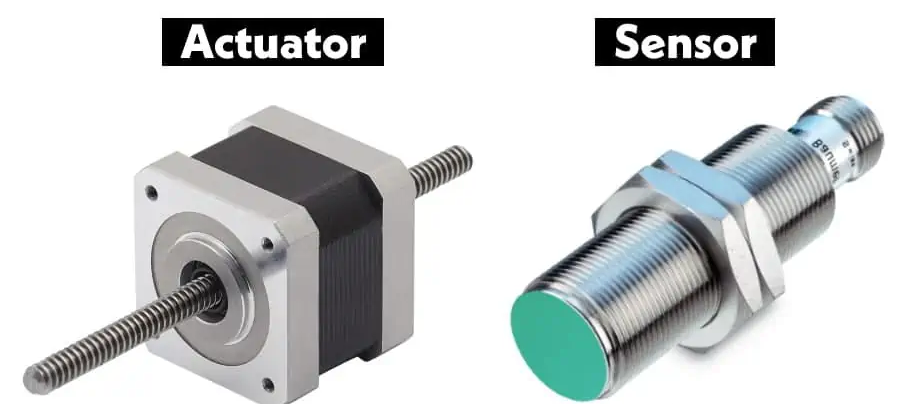

Sensors serve as the eyes and ears of automatic doors, ensuring that they open and close when needed, without causing inconvenience or harm. Various types of sensors with distinct mechanisms and functionalities are used in automatic doors.

Infrared Sensors

Infrared sensors mainly rely on infrared light waves to detect the presence or absence of an object. These are particularly effective in detecting warm bodies.

Components and Working

Emitter: Sends out infrared signals.

Receiver: Captures the reflected signals.

Microcontroller: Processes the signal to decide whether the door should open or close.

Advantages

Highly sensitive to heat

Generally low cost

Can work in various light conditions

Ultrasonic Sensors

Ultrasonic sensors use sound waves above the range of human hearing to detect objects or movement. These sensors often find application in environments where light-based sensors are less effective.

Components and Working

Transducer: Sends out high-frequency sound waves.

Echo receiver: Captures the reflected sound waves.

Processor: Compares the sent and received signals to make decisions.

Advantages

Effective in dim or highly lit environments

Can detect objects made of various materials

Highly accurate over short distances

Microwave Sensors

Microwave sensors use electromagnetic waves to detect motion or objects. These sensors have a longer range and can penetrate through walls and glass.

Components and Working

Transmitter: Emits microwave signals.

Receiver: Captures the reflected signals.

Digital Signal Processor: Interprets the received data to actuate the door.

Advantages

Long-range capability

Ability to see through some materials

Suitable for large and open spaces

Laser Sensors

Laser sensors employ a laser beam to detect objects or movement. These sensors are highly accurate and can measure the distance between the sensor and the object.

Components and Working

Laser Emitter: Sends out a focused laser beam.

Photodetector: Receives the reflected laser light.

Processor: Analyzes the data to determine distance and presence.

Advantages

Highly accurate

Can work over long distances

Suitable for specialized applications requiring precision

Overview of Actuators in Automatic Doors

Actuators are the muscles of an automatic door system, performing the crucial task of moving the doors based on signals from the sensors. Various types of actuators exist, each with their unique features, applications, and operational mechanisms.

Electric Motors

Electric motors are the most common actuators found in automatic doors, especially in sliding and telescopic types.

Components and Working

Motor unit: Converts electrical energy into mechanical movement.

Gear system: Increases torque for smoother and more efficient operation.

Control Unit: Dictates the speed, direction, and extent of movement based on sensor inputs.

Advantages

Highly efficient

Versatile and adaptable

Easy to install and maintain

Hydraulic Systems

Hydraulic systems usually appear in heavy-duty and high-traffic applications, often in swing doors and sometimes in sliding doors.

Components and Working

Hydraulic pump: Creates pressure in the hydraulic fluid.

Actuator cylinder: Converts hydraulic pressure into mechanical movement.

Valves: Control the flow and direction of hydraulic fluid.

Advantages

High force and torque

Durable and long-lasting

Efficient energy transfer

Pneumatic Systems

Pneumatic systems use compressed air to generate motion, and they’re often used in lighter applications like small swing doors or specialized medical facilities.

Components and Working

Air compressor: Generates compressed air.

Pneumatic cylinder: Converts air pressure into linear or rotational motion.

Regulator: Maintains consistent air pressure for smooth operation.

Advantages

Light and compact

Quick response time

Ideal for clean environments like medical facilities

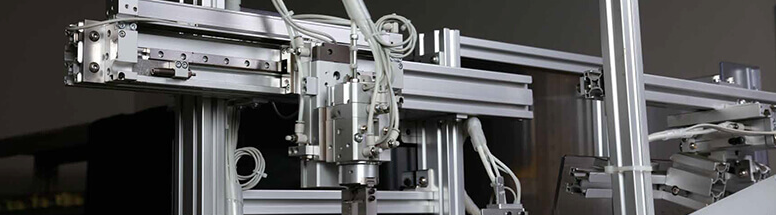

Sensor-Actuator Integration

The seamless integration of sensors and actuators is vital for the efficient operation of automatic doors. This involves hardware compatibility, software intelligence, and energy management. Each element is critical in ensuring that the doors function as expected, safely and reliably.

Hardware Integration

In the context of hardware, the integration involves establishing the physical connections between sensors and actuators.

Components and Working

Wiring: Connects the sensor outputs to the actuator inputs.

Circuit Boards: Host the electrical components and establish pathways for electrical currents.

Microcontrollers: Serve as the processing center to interpret sensor data and instruct the actuators.

Advantages

Enables quick response times

Simplifies troubleshooting

Facilitates modular upgrades

Software Integration

Software plays an essential role in interpreting the data from sensors and turning it into actionable tasks for the actuators.

Components and Working

Firmware: The embedded software that operates the sensors and actuators.

Logic Algorithms: Determine the conditions under which the doors should open, close, or remain static.

User Interface: Allows manual control and monitoring of the system.

Advantages

Enables smart features like traffic analysis and energy-saving modes

Makes the system adaptable to different environments

Provides a platform for future updates and features

Energy Management

Managing the energy consumption of the entire automatic door system is crucial for sustainability and operational efficiency.

Components and Working

Power Supply: Ensures consistent electrical power to both sensors and actuators.

Energy Monitors: Keep track of energy consumption.

Battery Backup: Provides power in case of outages.

Advantages

Reduces operational costs

Minimizes environmental impact

Increases system reliability during power outages